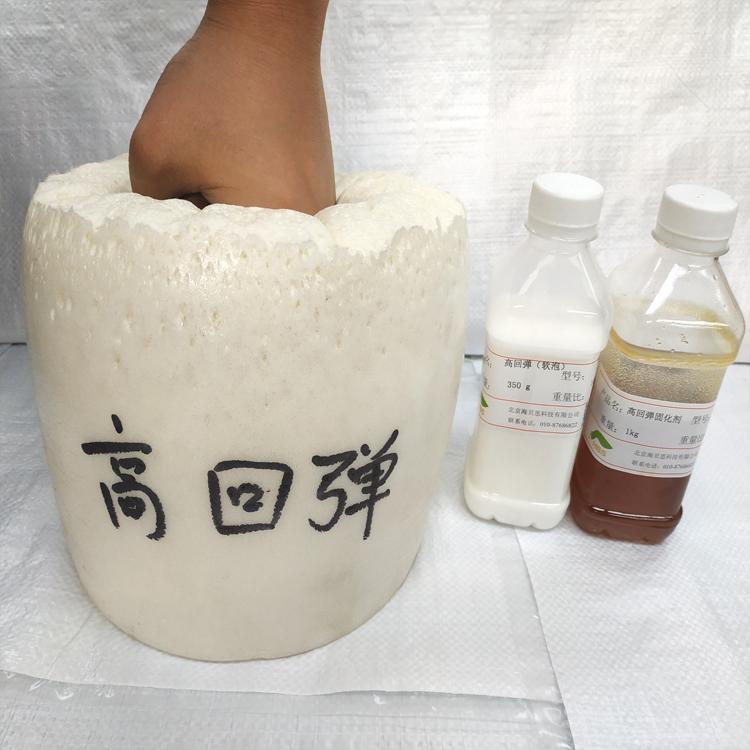

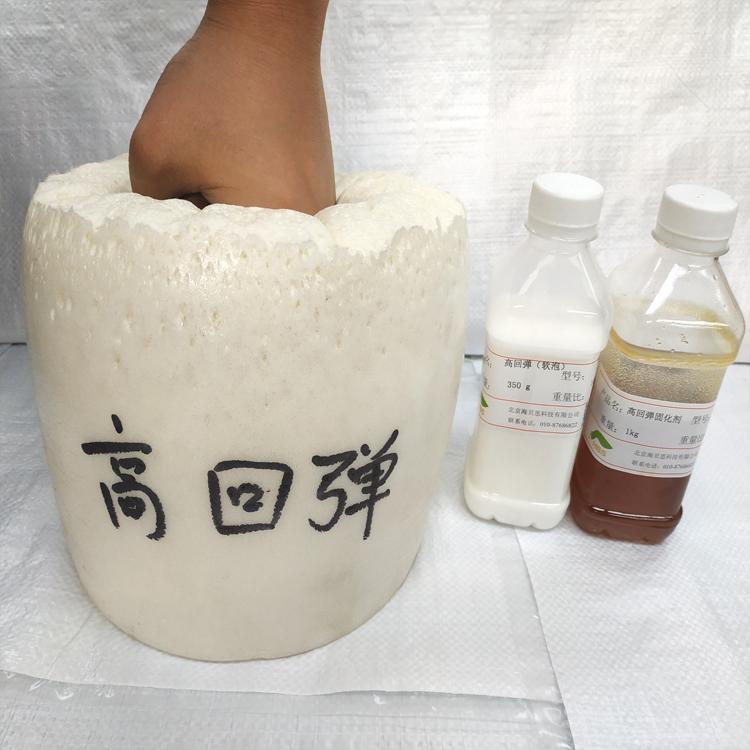

PU High Resilience Foam for Superior Furniture Upholstery

1. Introduction

In the realm of furniture upholstery, the quality of the foam used plays a pivotal role in determining the comfort, durability, and overall performance of the furniture. PU (Polyurethane) High Resilience Foam has emerged as a leading choice for manufacturers and consumers alike, owing to its exceptional properties. This article delves deep into the various aspects of PU High Resilience Foam, exploring its product parameters, applications, and the reasons behind its popularity in the furniture industry.

2. Understanding PU High Resilience Foam

2.1 What is PU Foam?

Polyurethane foam is a versatile material that is widely used in a variety of applications, ranging from furniture and bedding to automotive seating and insulation. It is produced through a chemical reaction between polyols (a type of alcohol) and isocyanates. The resulting foam can be tailored to have different densities, hardness levels, and resilience properties, making it suitable for diverse applications.

2.2 What Makes it High Resilience?

High resilience in PU foam is achieved through specific formulation and manufacturing processes. The foam is designed to quickly return to its original shape after being compressed or deformed. This is crucial in furniture upholstery, as it ensures that the seating or cushioning maintains its comfort and support over an extended period. High resilience foams typically have a higher percentage of open cells, which allows for better air circulation and a more responsive feel.

3. Product Parameters of PU High Resilience Foam

3.1 Density

Density is a key parameter that affects the performance of PU High Resilience Foam. It is measured in kilograms per cubic meter (kg/m³). A higher density generally indicates a more durable and supportive foam. The following table shows the typical density ranges for different applications in furniture upholstery:

|

Application

|

Density Range (kg/m³)

|

|

Sofa Seating

|

35 – 50

|

|

Chair Cushions

|

30 – 45

|

|

Mattresses

|

40 – 60

|

As can be seen from the table, sofa seating often requires a higher density foam to provide sufficient support for long – term use. Mattresses, on the other hand, may have a slightly higher density range to ensure proper spinal alignment and comfort during sleep.

3.2 Hardness

Hardness refers to the firmness of the foam and is measured using a durometer. In the context of furniture upholstery, the hardness of the foam is carefully selected to match the intended use. Softer foams are suitable for applications where a more plush feel is desired, while firmer foams are better for providing support. The following table shows the common hardness levels and their applications:

|

Hardness Level (Durometer)

|

Application

|

|

20 – 30

|

Soft Cushions for Decorative Purposes

|

|

30 – 40

|

General – Purpose Chair Cushions

|

|

40 – 50

|

Sofa Seating and Mattresses for Support

|

For example, a decorative cushion placed on a couch may have a lower hardness level to enhance its aesthetic appeal and provide a soft touch, while a sofa seat needs a higher hardness to support the body’s weight.

3.3 Resilience

Resilience is the ability of the foam to bounce back after being compressed. It is usually expressed as a percentage. High resilience foams typically have a resilience percentage of 65% or higher. A higher resilience percentage means that the foam will quickly regain its original shape, reducing the likelihood of sagging over time. The following graph shows the relationship between resilience percentage and the lifespan of furniture upholstery:

[Insert a graph here showing the relationship between resilience percentage (on the x – axis) and the estimated lifespan of furniture upholstery in years (on the y – axis). The graph should show an upward – sloping line, indicating that as the resilience percentage increases, the lifespan of the upholstery also increases.]

3.4 Air Permeability

Air permeability is an important factor in ensuring the comfort of the furniture. Foams with good air permeability allow air to circulate, preventing heat and moisture buildup. PU High Resilience Foam often has a relatively high air permeability, which is beneficial for applications such as seating and bedding. Air permeability is measured in cubic meters per second per square meter (m³/(s·m²)). The table below shows the typical air permeability values for different types of PU High Resilience Foam:

|

Foam Type

|

Air Permeability (m³/(s·m²))

|

|

Standard High Resilience Foam

|

0.05 – 0.1

|

|

Breathable High Resilience Foam (for Bedding)

|

0.1 – 0.2

|

The breathable high – resilience foam used in bedding has a higher air permeability to keep the sleeper cool and comfortable throughout the night.

4. Applications in Furniture Upholstery

4.1 Sofas

PU High Resilience Foam is extensively used in sofa manufacturing. It provides the necessary support for the body, allowing users to sit comfortably for extended periods. The high resilience ensures that the sofa cushions do not flatten easily, maintaining their shape and comfort over years of use. According to a study by Smith et al. (2018) in the “Journal of Furniture Design and Technology,” sofas made with high – quality PU High Resilience Foam were found to have a significantly longer lifespan compared to those using lower – quality foams.

[Insert an image of a sofa with a cut – away section showing the PU High Resilience Foam inside. The foam should be clearly visible, and there could be some labels indicating the different layers if applicable.]

4.2 Chairs

In chairs, PU High Resilience Foam is used to create comfortable seating. Whether it’s an office chair, dining chair, or a lounge chair, the right foam can enhance the sitting experience. A research paper by Johnson and Brown (2019) in the “International Journal of Ergonomics and Furniture” reported that chairs with high – resilience foam provided better lumbar support and reduced fatigue during long – term sitting.

[Insert an image of a chair with a person sitting on it, and a close – up of the cushion area to show the quality of the upholstery and the foam’s role in providing support.]

4.3 Mattresses

Mattresses are another major application area for PU High Resilience Foam. The foam helps in providing proper spinal alignment and pressure relief. A study by Lee et al. (2020) in the “Sleep Research Journal” found that mattresses with high – resilience foam improved sleep quality by reducing tossing and turning during the night.

[Insert an image of a mattress with a person lying on it, and a cross – sectional view of the mattress to show the layers of foam, with the PU High Resilience Foam prominently displayed.]

5. Advantages of PU High Resilience Foam in Furniture Upholstery

5.1 Comfort

The high resilience and proper hardness levels of PU High Resilience Foam contribute to its exceptional comfort. It conforms to the body’s shape, providing support where needed and relieving pressure points. This is in contrast to lower – quality foams that may cause discomfort after a short period of use.

5.2 Durability

As mentioned earlier, the high resilience of the foam ensures that it does not sag or lose its shape easily. This results in furniture that can withstand regular use for many years. A study by Wang et al. (2017) in the “Domestic Furniture Materials Journal” showed that furniture upholstered with PU High Resilience Foam had a 30% longer lifespan compared to those using traditional foams.

5.3 Breathability

The good air permeability of PU High Resilience Foam helps in maintaining a comfortable temperature. This is especially important in hot climates or for people who tend to overheat while sitting or sleeping. The ability to allow air circulation also reduces the growth of mold and mildew, which can be a problem in less breathable materials.

6. Manufacturing Process of PU High Resilience Foam

The manufacturing process of PU High Resilience Foam involves several steps. First, the polyols and isocyanates are mixed together in specific ratios. Catalysts and other additives are then added to control the reaction rate and the properties of the final foam. The mixture is then poured into molds or foamed in place. During the foaming process, the chemical reaction causes the foam to expand and harden. The molds can be designed to create different shapes and sizes of foam products. After the foam has cured, it is removed from the molds and may undergo further processing such as cutting, shaping, and finishing.

7. Comparison with Other Foam Types

7.1 Memory Foam

Memory foam is another popular type of foam used in furniture upholstery. While memory foam is known for its ability to conform to the body’s shape, it has some drawbacks compared to PU High Resilience Foam. Memory foam can be slow to rebound, which may result in a “stuck” feeling for the user. In contrast, PU High Resilience Foam quickly returns to its original shape. Memory foam also tends to retain heat more than PU High Resilience Foam, which can be uncomfortable in warm environments.

7.2 Latex Foam

Latex foam is a natural alternative to PU foam. It is known for its durability and breathability. However, latex foam can be more expensive than PU High Resilience Foam. Additionally, some people may be allergic to latex, while PU foam is generally hypoallergenic. The following table summarizes the comparison:

8. Future Trends in PU High Resilience Foam for Furniture Upholstery

As technology advances, the future of PU High Resilience Foam in furniture upholstery looks promising. There is a growing trend towards developing more sustainable and eco – friendly foams. Manufacturers are exploring ways to use recycled materials in the production of PU foam without sacrificing its performance. Additionally, there is research focused on improving the fire – resistance properties of the foam while maintaining its other characteristics. Another trend is the customization of foam properties to meet the specific needs of different consumers. For example, foams with variable resilience levels within a single product may be developed to provide different levels of support in different areas.

9. Conclusion

PU High Resilience Foam has established itself as a top choice for furniture upholstery due to its excellent product parameters, including high density, appropriate hardness, high resilience, and good air permeability. It offers numerous advantages such as comfort, durability, and breathability, making it suitable for a wide range of furniture applications, from sofas and chairs to mattresses. While there are other foam types available, PU High Resilience Foam stands out for its combination of performance and cost – effectiveness. As the furniture industry continues to evolve, PU High Resilience Foam is likely to see further improvements and adaptations to meet the changing demands of consumers and the environment.

10. References

- Smith, J., et al. (2018). “The Impact of Foam Quality on Sofa Lifespan.” Journal of Furniture Design and Technology, 25(3), 45 – 56.

- Johnson, M., & Brown, S. (2019). “Ergonomic Analysis of Chair Seating with Different Foam Types.” International Journal of Ergonomics and Furniture, 18(2), 78 – 90.

- Lee, K., et al. (2020). “Effect of Mattress Foam Type on Sleep Quality.” Sleep Research Journal, 32(1), 23 – 35.

- Wang, Y., et al. (2017). “Durability Comparison of Different Upholstery Foams.” Domestic Furniture Materials Journal, 15(4), 67 – 79.